Hydraulic Lifting Equipment (Jacking system)

Description

Hydraulic lifting equipment is mainly used for all kinds of flip large storage tank, gas holder, power plant desulfurization tower steel structure lifting installation. The installation of large weights is also generally adopted by this technique.

Features

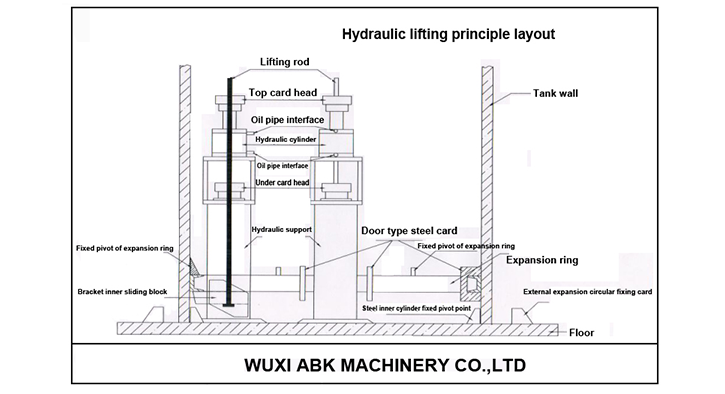

1. Hydraulic lifting device with feed through structure: Jack central hollow, steel wire inserted through the center of the jack. The upper and the lower clamping devices are integrated with the lifting jack, and the main top is connected with the steel wire by the claw plate of the upper and lower clamping devices. The hanging piece is connected with the steel wire through the component clamping device.

2. The power system is a pump station with all kinds of hydraulic valves, which controls the oil device through the action of the electromagnetic valve, and the jack cylinder and the clamping oil cylinder action are made.

3. The control system includes the console, start pumping box, inductor and connecting cables, which receives from the sensor information, instructions of the solenoid valve for the corresponding action, so as to control the whole system in the coordination.

Application

Hydraulic lifting equipment is installed in the absorption tower 0 meters on the ground, using the flip method to enhance the installation. The processing is done on the ground, including coil, rust, welding, butt joint, reinforcement welding, welding and other processing ring, to avoid high-altitude operations and improve the efficiency of construction. It has very high security in the construction and operation process.

Advantages

1. The hydraulic lifting equipment is a set of hydraulic, electrical and control technology as a whole new type of lifting equipment.

2. Hydraulic lifting device can carry large heavy pieces of vertical lifting and emplacement in difficult operating conditions.

3. It features small volume, light weight, heavy capacity, easy installation, high degree of automation, simple operation, safe and reliable performance.

4. Tank using hydraulic pressure to relax, tighten the top of the way to upgrade.

5. The lifting jack has a dual card insurance, even if a sudden power failure or fracture, which can ensure the lifting objects will not fall, featuring high safety factor and good synchronization.

6. Tanks along the track to climb up has good stability. Maximum lifting weight is 2 times the amount of the tank, to achieve the safety factor of hydraulic lifting.

Teshnical parameters of jack models

| Model/Description | ABK-JS25 | ABK-JS35 | ABK-JS50 | ABK-JS100 |

| Working capacity(metric tons) | 16 | 23 | 33 | 66 |

| Testing load(metric tons) | 25 | 35 | 50 | 100 |

| Standard arc distance between jacks(m) | 2 to 4 | |||

| Max plate for which jacking equipment can be supplied(m) | 2.6 or more | |||

| Min plate that can be used(m) | 0.10 | |||

| Plate thickness range(mm) | 5 and above | |||

| Unitary climb(cm/stroke) | 10 | |||

| Time per stroke(second) | 50 to 80 | |||

| Piston retracting system | Spring | |||

- H Beam Welding LineThis H beam welding line, also called H beam steel structure production line, is specially used for welding assembled H-type beams, I-type beams...

- Welding EquipmentWuxi ABK Machinery Co.Ltd can provide various welding machines for you to choose, including welding manipulator, welding positioner, welding...

- Pipe Welding EquipmentAs a professional welding equipment manufacturer in China, Wuxi ABK Machinery Co.Ltd can provide various high-quality pipe welding...

- CNC Cutting MachineAs a professional manufacturer of CNC cutting machine in China, Wuxi ABK Machinery Co.Ltd can provide various cutting machines...

English

English Español

Español Русский

Русский Português

Português Français

Français Thailand

Thailand Việt

Việt Indonesia

Indonesia